The Australian shipbuilding industry which had begun with the launch of the 10 ton Rose Hill Packet in 1789 continued to grow with the establishment of the Colonial Government's shipyard in 1797 and the following year the first privately owned shipyard was opened by James Underwood at Pyrmont NSW.

On August 1, 1839 The Hunter River Steam Navigation Company 'for the purpose of building or purchasing such steam vessels as may be found necessary to ply between Sydney and Hunter River' was formed and operated sister paddle ships Rose, Thistle and Shamrock, each of 200 tons.

An historic event occurred on February 16 1853, when the Ballarat, a 130 ton steamer, was launched from the company's works at Pyrmont. She was an iron steamer, the ribs and plates for which were brought out from England in Yarra Yarra and she was put together at Pyrmont, her engines came from the Raven, which had been wrecked on the Macleay River Bar. Her launching created great interest in Sydney and was indeed another milestone in the nautical affairs of the colony.

The ship building industry, although active in various States, did not expand significantly until, in 1911, a naval ship building programme was introduced at Cockatoo Island, the first vessel launched being the destroyer Warrego.

Just prior to the Second World War the Broken Hill Proprietory Company opened a ship building yard at Whyalla and Evans Deakin in Brisbane shortly afterwards. These two companies constructed 74 merchant vessels over 300 tons gross in the period 1942-1972. The Whyalla works built a number of ships over 50,000 tons d.w. such as Bogong bulkcarrier 55,000 tons launched 1967 and Amanda Miller tanker 65,748 tons launched 1971. The largest vessel constructed by Evans Deakin over the 30-year period was The Robert Miller, a sister ship to the Amanda Miller mentioned above.

The principal Australian ship building yards in recent times are the Vickers Cockatoo Dockyard Pty. Ltd., Sydney, Williamstown Dockyard Victoria, Carrington Slipway at Newcastle, Australian Shipbuilding Industries Kwinana, W.A., and North Queensland Engineers and Agents Cairns, Queensland. The BHP Whyalla and Evans Deakin shipyards ceased operation in 1978 and 1976 respectively, and in 1987 the N.S.W. State Government announced the closure of the State Dockyard at Newcastle.

Since 1970 Australia's large shipbuilding capacity has suffered a major decline. Construction of large vessels has been phased out and the industry is reduced to speciality craft and naval vessels.

Edward Dayes' 1804 engraving. State Library of NSW.

As early as December 1788, Robinson Reid, the carpenter from the Supply, built Sydney's first boatshed, which was on the eastern shore. Out of this tiny hut, he then built the famous Rose Hill Packet, launched in October 1789 and subsequently employed in transporting provisions to Parramatta. According to the Deputy Judge Advocate David Collins, the convicts christened her with this tongue-in-cheek name. The ship also became known as 'the Lump', a fact that does not speak highly of Mr Reid's boatbuilding skills. In 1793 the Francis was assembled and launched, after being sent out on the Pitt in frame, to sail largely between Sydney and Norfolk Island.

Go There

In 1861 Williamstown had 13 slips for boat repairs and building, and pier accommodation for 40 vessels. By 1870, Williamstown was known as the major cargo port of Victoria, with piers, slipways, shipwrights, and gangs of wharfies, all working along the shore opposite Nelson Place. As well, the Customs Department, pilots, the Victorian Navy, and the Harbour Trust all established bases in Williamstown.

The foundation stone of the Alfred Graving Dock was laid on 4 January 1868 by HRH Prince Alfred, KG, Duke of Edinburgh, who arrived in the Royal Navy's first ironclad, HMS Warrior. Large excavations were necessary before the construction of the dock commenced. It was necessary to build an immense cofferdam, consisting of two curved walls, 1,000 feet (300 m) in length, constructed of hardwood sheeting five inches (127 mm) thick. It was completed in July 1869, when boilers, engines and pumps were placed in position and pumping operations commenced. The cofferdam continued to perform its important function until March 1872, when following a south westerly gale, a portion of the north western area collapsed, and the dock was flooded to within four feet of the top of the masonry.

It was subsequently discovered that the cofferdam in this section was erected over a vessel that had been sunk at the spot some years before. Four weeks elapsed before repairs were completed. When the water was pumped out, it was found that the masonry had not been appreciably damaged. The graving dock was completed on 14 September 1873, but the dock caisson was not finished and in position until February 1874. HMCS Nelson was the first to enter it (in 1874). Following the opening of the graving dock, many ships of various sizes and types were docked and repaired over the next 30 years.

The Alfred Graving Dock is historically significant as the first graving dock in Victoria and the third in Australia at that time, for its role in the development of the shipping industry in Port Phillip, for its continuous use as a Dockyard since its completion and for association with William Wardell during his term as Inspector General of the Public Works Department. In 1873,

Go There

Launch of HMAS Success, Cockatoo Island Shipyard, 1984

Cockatoo Island is the largest island in Sydney Harbour. Located at the junction of the Parramatta and Lane Cove rivers, Cockatoo Island has been put to a number of uses since colonisation, the remnants of which can be seen today. It has been a convict prison, industrial school and girls reformatory. Many buildings from this era remain and can be visited.

Cockatoo Island is also the site of one of Australia's biggest shipyards during the twentieth century. The first of its two dry docks was built by convicts and was completed in 1857. Large sections of the shipyard facility remain, including the two dry docks, the shipbuilding slipways and many of the buildings within the shipyard.

Shipbuilding began on Cockatoo Island in 1870. In 1913, Cockatoo Island was transferred to the Commonwealth Government to become the Naval Dockyard of the Royal Australian Navy. Over a period of several years prior to the First World War five slipways were either upgraded or constructed in the island, with Numbers 1 and 2 still retained today. The torpedo boat destroyer HMAS Warrego was the first naval ship launched at Cockatoo Island, after being built in the United Kingdom, disassembled, then sent to the Australian shipyard for reassembly.

When the shipyard closed in 1992, Cockatoo Island lay dormant for a decade until the Sydney Harbour Federation Trust was established and given the responsibility of revitalising this significant corner of Sydney Harbour. The Trust's rehabilitation of the island resulted in the creation of one of the most unusual places to visit in the city.

Go There

Whyalla shipbuilding yard, 1970

Whyalla is South Australia's second largest city and once a major industrial force with an iron ore smelter, steel rolling mill and shipyard. It is a large, sad sort of place that has spent many years struggling for survival - reddened, like a bruised eye, by the iron ore which is blown over the city from the steelworks. Driven by the local steel and petroleum industries, Whyalla has refused to die, and is still the largest provincial city in South Australia.

Between 1941-78 sixty-three ships were built at the Whyalla shipyard. At its peak Whyalla was the biggest shipbuilding port in Australia with a capacity to build ships up to 83,000 tonnes. The largest ship ever built in Australia, a bulk carrier called the Clutha Capricorn, was launched from the Whyalla shipyards in 1972. The most memorable was the ore carrier, MV Lake Illawarra, which collided with the Tasman Bridge in Hobart, Tasmania, on 5th January 1975, causing the deaths of 12 people. The ship and the debris pile were deemed unsafe to move, and remain at the bottom of the Derwent estuary.

Whyalla Maritime Museum has an excellent and comprehensive display, combines a history of local shipping (through models, photographs and audio visual displays) with a guided tour of the 650 tonne corvette HMAS Whyalla (the first ship built at Whyalla) and a huge model railway display.

Of all the ships built in Whyalla, the 650 tonne corvette HMAS Whyalla, the first ship completed at the shipyard, has become the most famous. It now stands like some kind of strange vessel which has lost its way glaring down over the Lincoln Highway at the northern entrance to the city.

Go There

Evans, Deakin shipyard, 1968

For many years the Brisbane suburb of Kangaroo Point was dominated by the factories of heavy engineering businesses, particularly those involved in the maritime industry, such as Buzzacott & Co, Evans Anderson & Phelan and shipbuilders Evans Deakin. Evans Deakin built the largest ship ever constructed on the Brisbane River, the 66,000 tonne oil tanker Robert Miller, which became adrift in the river during the 1974 Brisbane flood. The last vessel to be built by Evans Deakin was an oil rig called Southern Cross. The company vacated the site in 1976, with it later being redeveloped for high-rise accommodation. The now-flooded dry dock remains as a reminder of the area's former use and has been incorporated into the site's redevelopment.

The now-flooded Evans Deakin shipyards dry dock

Until the 1930s, Evans Anderson & Phelan built steam locomotives at their Kangaroo Point works for Queensland Railways, however their works were not located near a railway, so the completed locomotives were delivered along Main Street on temporary track. Until the federation of the Australian colonies in 1901, the Queensland Navy's main storage facility was located in the suburb. The first ship-based radio transmission in Australia was made between HMAS Gayundah and the buildings in 1903. The naval stores buildings were occupied by the Royal Australian Navy until 1959, and then by the Australian Army until 1984. The heritage-listed buildings are now used by an adventure company focusing on river activities and rock climbing.

HMAS Rockhampton on the builders slipway at the Walkers yard, Maryborough, Queensland, c.1941.

For many years, the Walkers shipbuilding yard was a major employer in the town of Mzryborough. Walkers began shipbuilding at Maryborough in 1877 on a 10 acre site fronting the Mary River, some 32 km upstream from the river's entrance to the sea in the Great Sandy Strait. They concentrated on building medium sized and special purpose vessels because the upstream location presented navigation difficulties when attempting to get larger vessels safely to the sea.

After World War 1, Walkers recommenced shipbuilding with two 6,600 ton ships, and a dredge in 1925, but little of significance after that. The shipyards were reactivated in 1939 when World War II began. They built seven corvettes and three frigates, and at the height of production employed 1200 men. HMAS Gladstone was one of 60 Australian Minesweepers (commonly known as corvettes) built during World War II in Australian shipyards as part of the Commonwealth Government's wartime shipbuilding programme. Twenty were built on Admiralty order but manned and commissioned by the Royal Australian Navy. Thirty-six (including Gladstone) were built for the Royal Australian Navy and four for the Royal Indian Navy. Gladstone was commissioned on 22nd March 1943.

HMAS Diamantina on display in the Queensland Maritime Museum's Dry Dock, South Brisbane

HMAS Diamantina, built in 1943, was one of three frigates built at the Maryborough shipyard towards the end of World War II. She was decommissioned in 1980 and then transferred to the Queensland Maritime Museum in South Brisbane, where she lies in the old drydock.

Walkers closed and sold off the Maryborough shipyard after a destructive flood caused much damage in 1974. Problems in addition to the flood damage were a growing shortage of work for Australian ship builders, plus difficulties producing the bigger ships that were in demand by this time. EDI Rail, formerly Walkers Limited, has in recent years built much of the rolling stock and locomotives for Queensland Rail.

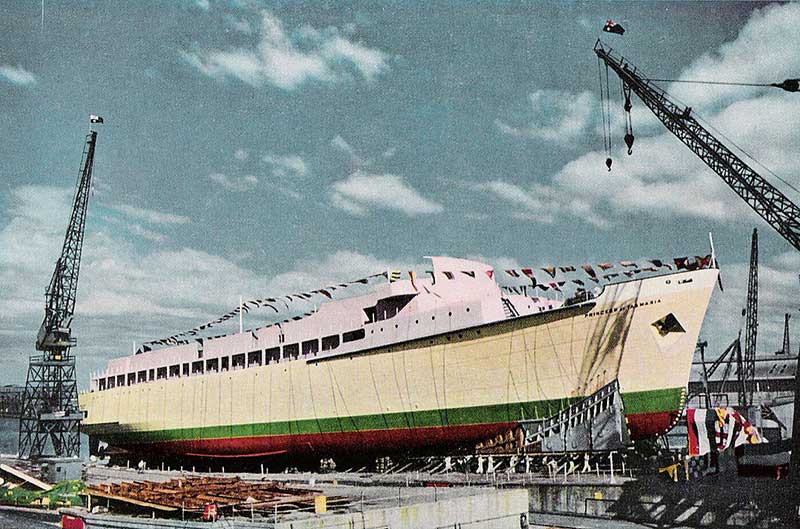

MS Princess of Tasmania under construction in 1958

The State Dockyard was a ship building and maintenance facility operated by the Government of New South Wales in Carrington, Newcastle, between 1942 and 1987. In 1942, the State Dockyard opened on the site of the Government Dockyard at Dyke Point in Newcastle that had closed in 1933. Officially the New South Wales Government Engineering & Shipbuilding Undertaking, it was universally referred to as the State Dockyard. The dockyard facility was located at Carrington on Newcastle Harbour, on 11 ha (27 acres) of land in addition to the ship repairs site on 3 ha (7 acres).

The dockyard launched its first vessel in July 1943. By the end of World War II, it had launched two ships for the Royal Australian Navy and 22 vessels for the United States and had repaired six hundred ships. A 15,000 ton floating dock was located at Dyke Point in 1943 to repair damaged ships during World War II. The floating dock was scrapped in 1977.

With the cessation of large scale shipbuilding, in the 1970s it diversified into other engineering disciplines. In November 1986 a team of apprentices from the Hunter Valley Training Company completed a three-year overhaul of steam locomotive 3801 at the dockyard. The dockyard closed on 3 March 1987.

As of 2014, the surviving State Dockyard built ships are Cape Don, a lighthouse tender built in 1962 for the Commonwealth Lighthouse Service which is now a museum ship at Balls Head Bay, Waverton. The ferries Lady Herron, Freshwater, Queenscliff, Narrabeen and Collaroy continue to operate for Harbour City Ferries, while former Sydney Harbour ferries Lady Cutler and Lady McKell operate as cruise boats on Port Phillip. Lady Herron and Lady Northcott are in store at Harbour City Ferries facility at Balmain. Lady Woodward has been converted to a private houseboat and is located at Tin Can Bay.

Located on Sydney's Lower North Shore, Woolwich is one of Sydney's wealthiest suburbs, a remarkable turnaround for what for many years was at the heart of Sydney's shipbuilding industry. Located 11 kilometres north-west of the Sydney central business district, Woolwich sits on the peninsula between the Lane Cove River and the Parramatta River, jutting out from Hunters Hill. Maritime industry including shipbuilding and a dry dock grew alongside residential development around the turn of the 20th Century.

Woolwich Dock

In 1888, the 10 acre eastern portion of Clarkes Point was sold to Davy & Co. iron founders. In June 1898, the site was purchased by Morts Dock and Engineering Company of Balmain, who began work on a planned new dry dock. This included reclamation work and sea wall construction. The dock was cut 175 metres directly into the sandstone, some 30 metres wide. 85,000 cubic metres of sandstone was excavated to create the dock.

On 4 December 1901 the dock was officially opened and used for the repair and fitting-out of large ships. Several extensions were carried out between 1902 and 1918 which saw the dock lengthened to its present 260 metres. After the Depression of the 1930s work did not pick up until World War II. At its busiest, the dock employed 1,500 people. New work declined again after the war and in 1958 the company ceased operations and went into voluntary liquidation.

The site lay idle until the Army purchased it in 1963 for its water based transport operations. The Army erected a number of prefabricated buildings and added timber fender piers, timber wharves and a travelling crane to the dock itself. In 1997-8 the 35 Water Transport Division was relocated to Townsville. The Harbour Trust has re-developed the whole of Clarkes Point as an historic re-creation of a maritime village.

Go There

Launch of HMAS Deloraine, 1942, Morts Dock, Balmain

By the mid 19th century Balmain had developed into Sydneys biggest maritime industrial/residential area, with clusters of workmens cottages standing cheek-by-jowl with the industries in which their tenants eked out a living. Every trade and occupation was represented in its population: not only the waterfront-related ones, like wharfies, seamen, coal lumpers, boilermakers, engineers, painters and dockers, etc., but also the wide variety of factory workers, miners, building trades, timber workers, stone masons, etc.

Boat yards, ship repair and ship building yards abounded around the foreshores of Balmain, as well as on Cockatoo Island and neighbouring headlands. Around Snails Bay and extending to the end of Longnose Point was the shipbuilding and ship repair facility of Morrison and Sinclair (1923-72). Many ferries were built here for the Balmain Ferry Company during the early part of the 20th century. A slipway at the end of Longnose Point is all that remains of this facility.

In the last 50 years, Balmain's shoreline has changed dramatically as one by one Balmains factories and workshops moved away from the inner city suburb. Parklands and blocks of residential units have replaced the factories, chimneys and cranes that once were so much a part of Balmains skyline. Just a handful of remnants have survived to remind present and future generations of Balmains unique blue collar maritime origins.

Morts Dry Dock

Mort Bay, once the hub of Sydneys shipbuilding industry, is located immediately south west of Goat Island where the Parramatta River enters Sydney Harbour. It is named after Thomas Sutcliffe Mort, the merchant and businessman who established the first dry dock in Sydney there in 1854. This was created by the excavation of sandstone near the head of Mort Bay. Morts Dry Dock was the first dry dock in Australia, opening for business in 1855 and closing more than a century later in 1959.

In 1957 the dock was closed and filled in. Remnants of the dock have been preserved in Mort Bay Park off Cameron Street, Birchgrove. These include the outline of the historic dry dock which is in fact the top of the dock wall and the steel caisson or dock gate. The nearby quarries at the head of Mort Bay which had supplied the stone for Balmains buildings and seawalls were taken over by shipyards after the dock was built. Today the shipyards have been replaced by blocks of luxury apartments which now cling to the towering quarry walls.

Go There

SS Montoro in Morts Dry Dock, 1911

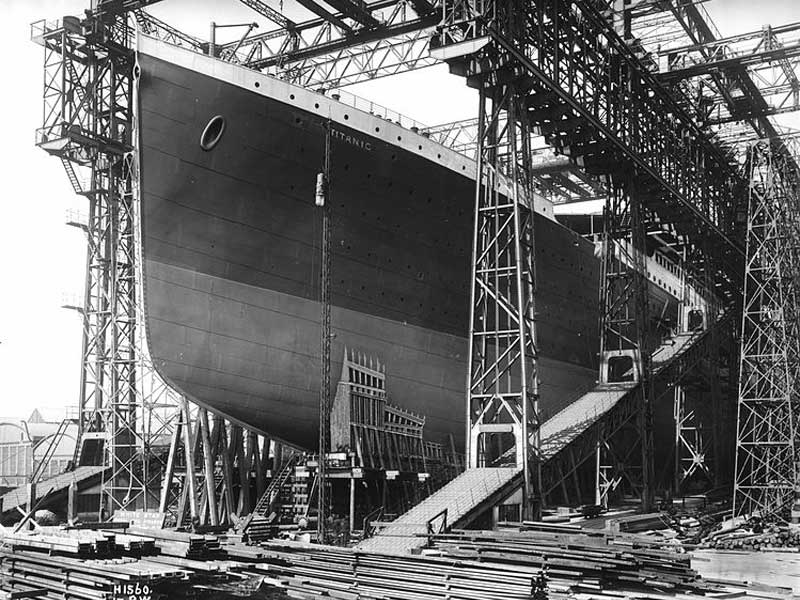

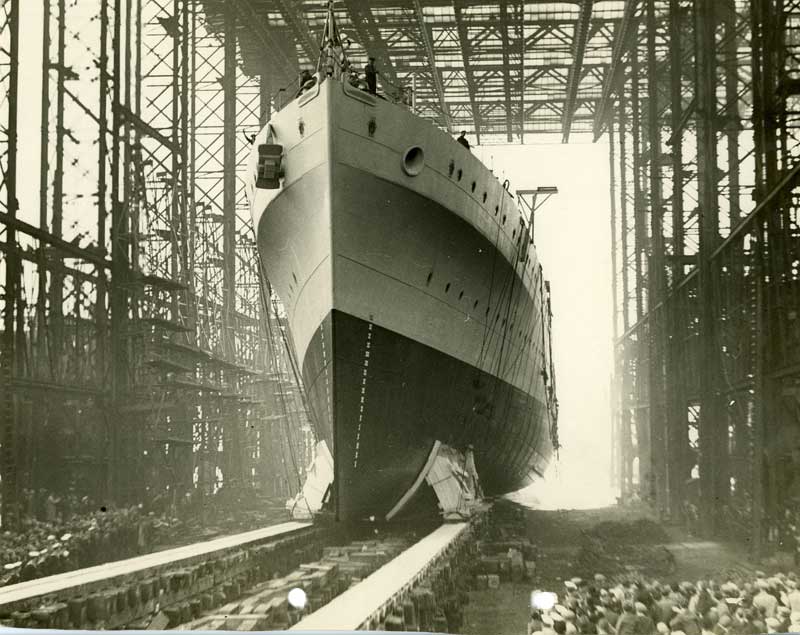

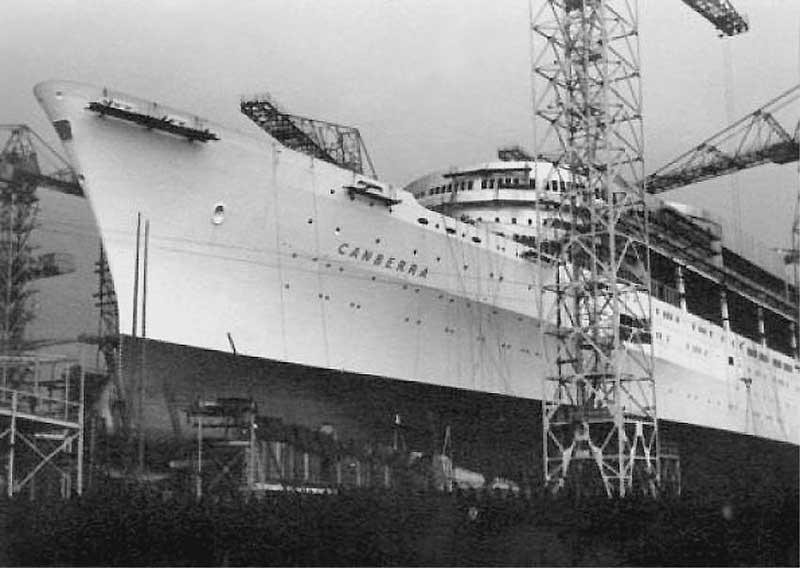

While the British shipbuilding industry has largely decamped to Asia, Britain's European neighbours still build ships. In 2020, some 53 ships were in the pipeline in Norway, with the majority of them specialist ships to service the North Sea oil industry, which, of course, it shares with Britain. The giant luxury cruise ships gracing Southampton docks are all mostly built in European shipyards. Cunard had wanted to build the Queen Mary 2 in a British shipyard. The only one able to was Belfast's Harland and Wolff, which built the iconic ships such as Titanic and Canberra, but the British Government failed to provide the guarantees necessary to build it and so the order went instead to French shipbuilders Chantiers De L'Atlantique in Saint-Nazaire.

RMS Titanic under construction, Belfast, 1911

Along with France, Germany's workforce has benefited from building passenger vessels. And unlike Britain these countries and others have also successfully exported warships. Dr Duncan Redford, senior research fellow at the National Museum of the Royal Navy, said: "Fundamentally warship building in the UK for many years has solely been about supporting the Royal Navy, but others have not just supported their own indigenous requirements but made a virtue of exporting its shipbuilding designs."

Spain has completed two 27,000 tonne Canberra Class Amphibious Assault Ship (LHD) for Australia, once big customers of British shipyards. The announced closure of BAE's shipbuilding operations in Portsmouth in 2016 ended more than 500 years of shipbuilding in Hampshire which included the construction of Admiral Lord Nelson's warships at Buckle's Hard in the New Forest and 100 years of shipbuilding in Woolston, Southampton, by the company latterly known as Vosper Thornycroft. It also signified another chapter in the decline in British sea power. A century ago Britannia really did rule the waves with two-thirds of the world's ships flying the red duster.

University of Southampton historian John McAleer, a former curator at the National Maritime Museum in Greenwich, said: "I think that is what is niggling people as well as the obvious worries about jobs and industry. Britain's maritime heritage is Britain's history. The two are absolutely interlinked."

So what went wrong for this once mighty industry? The reality is that British shipbuilding has been in trouble since after the Second World War.

Some say it was industrial strife between management and unions. Others blame lack of investment in new equipment and cost effective manufacturing techniques. But the general consensus is that Britain's ships were too expensive and that huge new shipyards in the emerging economies of Japan and South Korea, were simply producing cheaper ships by the 1970s.

SS Strathmore under construction, Barrow-in-Furness, 1935

The crunch for commercial British shipbuilding came in the 1980s with a double whammy of world recession and a strong pound making Britain's ships too expensive. The battle between disruptive unionisism and Margaret Thatcher's Tory Government didn't help. The labour party was determined to cripple the profits of business by any means and their method was to disrupt every possible enterprise involving mass labour through disruptive unionisation. The Thatcher Government was equally determined to crush the power of the unions, and their battle resulted in the destruction of the marine industry among others. Mass labour businesses nearly all vanished, shipbuilding among them. Anybody wanting to run anything involving thousands of people even today is still faced with the hostility of unions who appear to have learnt nothing.

The final nail in the offin of ship building and repairing in the UK was the stopped of the subsidy of the ship building industry by the Thatcher government (this subsidy also gave the right for government to use those ships in times of war). Other countries that build ships still give there shipbuilding industry subsidies, which gives them the legal right to call on the ships use if they are in a war. Ironiclly, the UK is a world leader in ship design and technology, its new RFA ships were designed there. Cunard's Quen Mary 2 was designed there and is packed with British technology and craftsmanship.

But leading shipbuilding expert Dr Martin Stopford, who worked in the industry for decades, says the opportunity for Britain to build ships again has probably gone forever: "The price we could sell a bulk carrier for would just buy the materials to build it." While strict European Union subsidy rules for shipbuilding were observed in the UK, he says other countries were less transparent than Britain and a little cleverer at funnelling subsidies into their yards. Meanwhile he said countries such as Germany, France and Italy had made a strategic decision to build cruise ships which is something their Asian counterparts were unable to do.

"As the cruise ship industry boomed they (the European shipyards) could supply the vessels, while Britain's yards had missed the boat. After shipbuilding in Portsmouth stops next year, just two BAE systems shipyards in Glasgow and one submarine builder in Barrow in Furness will be holding the flame of a once mighty industry. They will continue to build cutting-edge warships into the next decade but represent a tiny fraction of what once was. The irony for British shipbuilding is that while Britain's industry has fallen behind, we are entering a golden age of shipping with tens of thousands of vast container ships criss-crossing the globe carrying goods between continents."

The giant Titan crane, the sister to the one then once stood at Sydney's Garden Island Naval Base, is one of the few relics remaing from the giant John Brown ship building facility than once stood on the banks of the Cyde at Glasgow, Scotland. The crane was used to place the engines in many iconic ocean liners built at the John Brown shipyards, including the Queen Mary, the original Queen Elizabeth, the Lusitania, HMS Hood and HMS Repulse. The last of these great ships to be built here was the Queen Elizabeth 2 (QE2). At its height, from 1900 to the 1950s, it was one of the most highly regarded, and internationally famous, shipbuilding companies in the world. Today, the Titan crane is used for bungie jumping.

SS Queen Elizabeth 2, September 1967

The Clydebank Titan crane today

Barrow-in-Furness is an insustrial town on England's Cumbian coast to the south west of the Lake District. It was here that the ship RMS Strathaird, the P&O liner on which my family and I migrated to Australia in May 1960. I have fond memories of the trip, which had kindled his life-long interest in ships and things maritime-related, so to visit the place where it all started had always been a goal of his.

As with other similar localities around the UK, the shipyards are long gone but museums recall the days when shipbuilding provided work for thousands of people in ports around the British Isles. Here at Barrow-In-Furness, the Dock Museum keeps the memory of those days alive. Familiar names of many ships that brought migrants to Australia - Orion, Orsova, Oriana, Himalaya, Chusan, and of course the four Strath sisters - all are honoured at the place where they were built and launched.

Barrow slipways

The same site today

Sunderland was once the biggest shipbuilding town in the world. Now the banks of the River Wear stand empty and silent. It all started back in 1346, when Thomas Menvill had a shipbuilding yard in Hendon. Throughout its history Sunderland has had over 400 registered shipyards. Between 1846-64, Wearside ship builders produced almost one third of all ships ever made in Britain. The 1850s were the best years, with 1,536 ships being built during the decade.

The world-famous Liberty Ship was among the designs to be created, produced and manufactured at the Thompson and Son's yard's at North Sands. Liberty ships, a type of mass-produced cargo ships built to inexpensively meet the United States' World War II maritime transport needs. Throughout the 1950s and 1960s many yards closed or merged. In 1977 the shipbuilding industry was nationalised and job losses followed. In 1980 the last two remaining yards merged, then only eight years later on the 7 December 1988 this last remaining yard on the Wear closed bringing shipbuilding in Sunderland to a sad closure. Where Sunderland University's St Peters Campus and The National Glass Centre now stand on the River Wear, was where the site of the last ship building yard.

Launch of 'Sir Archibald Page', 1950

The same site today

Wallsend, historically Wallsend on Tyne, is an area in North Tyneside. Historically part of Northumberland, Wallsend derives its name as the location of the end of Hadrian's Wall. Wallsend has a history of shipbuilding and was the home of the Wigham Richardson shipyard, which later amalgamated to form Swan Hunter & Wigham Richardson, probably best known for building the RMS Mauretania. This express liner held the Blue Riband, for the fastest crossing of the Atlantic, for 22 years.

Other famous ships included the RMS Carpathia which rescued the survivors from the Titanic in 1912, and the icebreaker Krasin (launched as Sviatogor) which rescued the Umberto Nobile expedition on Spitzbergen in 1928, when Roald Amundsen perished. The story is retold in the movie The Red Tent, starring Sean Connery and Peter Finch. WWII ships built here include HMS Sheffield and HMS Victorious which took part in the sinking of the Bismarck. Other ships built there include the new HMS Ark Royal in the 1980s. The shipyard closed in 2007. The former Wallsend Slipway & Engineering Company Shipyard continues to operate, constructing offshore oil rigs and as a TV studio, productions from there include the hit ITV drama Vera starring Brenda Blethyn and Inspector George Gently starring Martin Shaw.

HMAS Sydney takes to the water for the first time, 22 September 1934

The same location today

Harland & Wolff is most famous for having built all of the ships intended for the White Star Line including RMS Titanic. Other well known ships built by Harland & Wolff include Titanic's sister ships RMS Olympic and RMS Britannic, the Royal Navy's HMS Belfast, Royal Mail Line's Andes, Shaw Savill's Southern Cross, Union-Castle's RMS Pendennis Castle, and P&O's Canberra. Harland & Wolff was formed in 1861 by Edward James Harland (1831-95) and Hamburg-born Gustav Wilhelm Wolff (1834-1913). In 1858 Harland, then general manager, bought the small shipyard on Queen's Island from his employer Robert Hickson.

P&O liner SS Canberra under construction, October 1959

In 1912, the three neighbouring yards were amalgamated and redeveloped to provide a total of seven building berths, a fitting-out basin and extensive workshops. It was during this period that the company built Olympic and her sister ships Titanic and Britannic between 1909 and 1914, commissioning the construction of a massive twin gantry and slipway structure for the project. In the First World War, Harland and Wolff built monitors and cruisers, including the 15-inch gun armed "large light cruiser" HMS Glorious. The shipyard was busy in the Second World War, building six aircraft carriers, two cruisers (including HMS Belfast) and 131 other naval ships; and repairing over 22,000 vessels. It also manufactured tanks and artillery components. It was in this period that the company's workforce peaked at around 35,000 people.

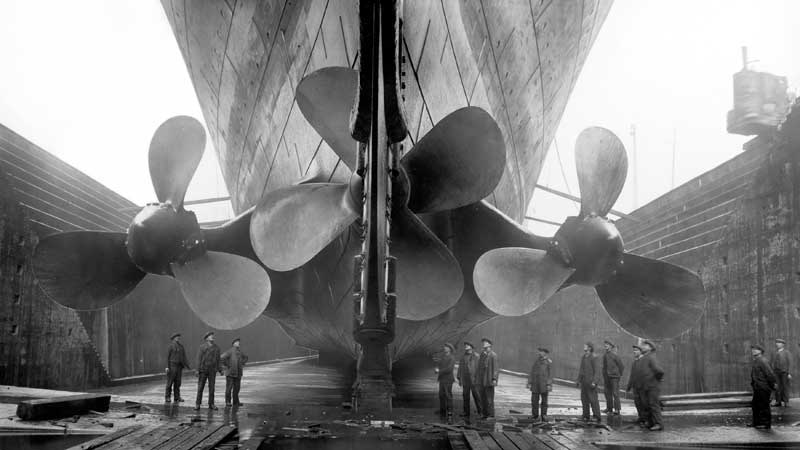

RMS Titanic's Propellers, 1911

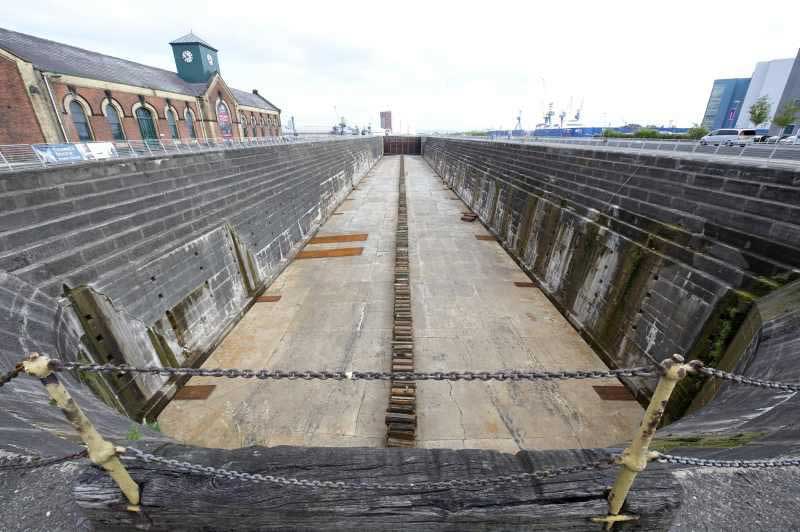

Thompson Graving Dock, Belfast. When built in 1911 for RMS Titanic, it was the largest dry dock in the world.

The last liner launched by the company was MV Arlanza for Royal Mail Line in 1960, whilst the last liner completed was SS Canberra for P&O in 1961. The company was bought from the British government in 1989 in a management/employee buy-out in partnership with a Norwegian shipping magnate. By this time, the number of people employed by the company had fallen to around 3,000. The company bid unsuccessfully tendered against Chantiers de l'Atlantique for the construction of Cunard line's new Queen Mary 2 in 2001.

Turbines for the Ormonde Offshore Windfarm being assembled at Harland & Wolff, Belfast.

Design by W3layouts